POLARDRY ELECTROSTATIC DRYING TECHNOLOGY

POLARDRY ELECTROSTATIC DRYING TECHNOLOGY

Efficient drying technology for pharmaceuticals and thermosensitive materials

Mild-temperature PolarDry® electrostatic dryers are ideal for heat-sensitive and oxygen-sensitive material including living microorganisms, probiotics, and proteins. It’s a high-throughput alternative to lyophilization/freeze drying or conventional spray drying.

The benefits of PolarDry

PolarDry® can overcome the inherent challenges of traditional drying processes. This new electrostatic drying technology can produce powders faster and at temperatures that are optimal for the active ingredients—to retain activity, increase production yield, avoid cold storage and transportation, or make powders for controlled release or inhalation applications.

It’s gentle enough for the most demanding scenarios that are encountered in drying pharmaceuticals, biologics and other high-stakes powders. Drying is now possible for products that were a challenge to dry with conventional methods while maintaining high production yields and capacities.

And for those materials that require solvents upstream, PolarDry® enables faster production by eliminating evaporation and concentration steps while maintaining high bioavailability and activity.

How it looks in real-time

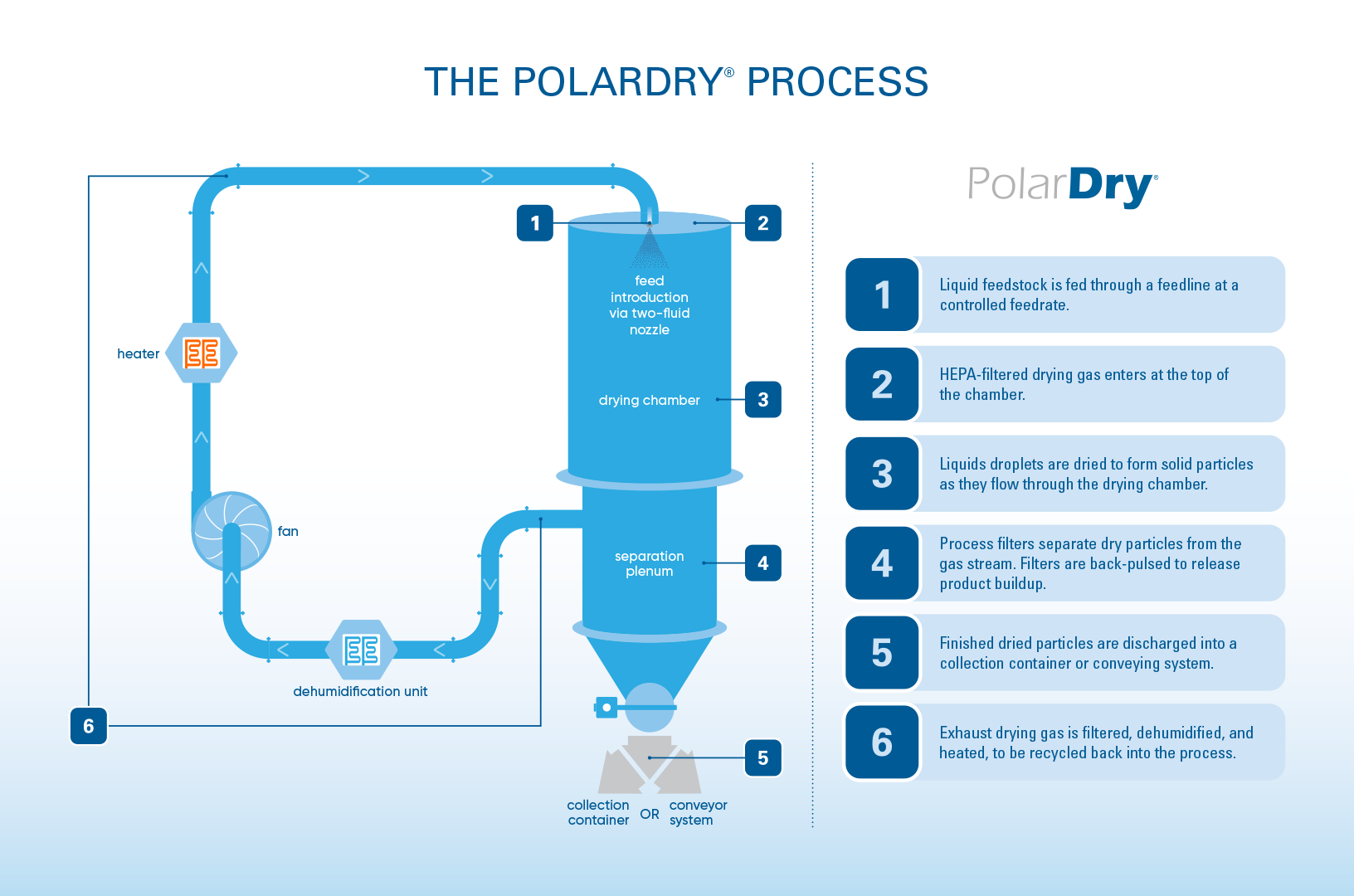

In the PolarDry® drying process, an electrostatic charge is dispensed to the droplets as they are formed. Dried powder particles are formed as the droplet travels to the bottom of the dryer. Solids in the droplet are pushed inward while liquids migrate to the outside toward the atomizing and drying gas streams.

Because liquids are forced outward, they form a protective layer for the active components against the temperatures in the drying chamber.

As the particles flow through the chamber, vaporized liquids cool the chamber. The resulting lower outlet and product temperatures provide additional protection for the dry active components.

PolarDry features

Multiple model scales:

PolarDry electrostatic dryers are available in models from lab-size to production scale

Modular design:

Fits into continuous manufacturing or batch production lines

Preserves product quality:

Prevents the active component degradation and denaturation that can happen with traditional drying methods

Versatile:

Works with aqueous and solvent applications

Ideal for new and existing products:

Innovations that could not be produced by conventional drying methods can be ideal for PolarDry’s moderate temperatures, fewer processing steps and desired particle sizes

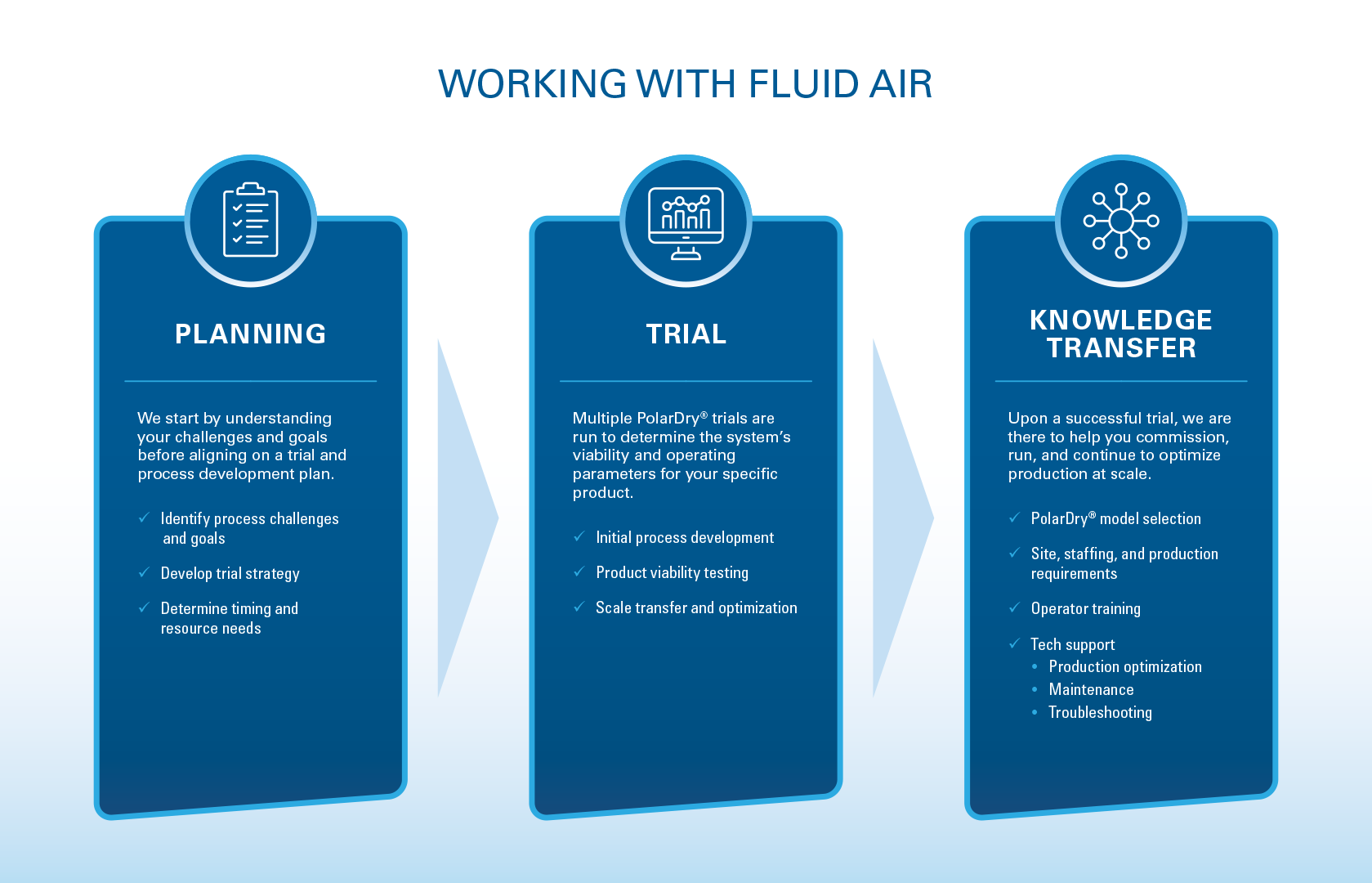

Expert customer support:

Fluid Air offers feasibility and development assistance through the lab trial process, equipment training, continued process and equipment support through the equipment lifecycle

Ask about PolarDry before expanding your production, standing up a new line, or dismissing a new product idea as impractical.

FAQ

Does Fluid Air help me provide projections and data for my executive team, to show ROI and payback periods?

Yes.

How does it differ from traditional drying processes?

PolarDry operates within a product temperature range of 45-100°C, distinctively different from the temperature extremes of lyophilization and conventional spray drying.

How large are PolarDry® batches?

With PolarDry®, you need not do batch processing, you can operate it as a continuous production system. You can also switch to other production runs much faster than with traditional methods.

How does the PolarDry system work?

PolarDry Model 0.1

This portable, PLC-controlled, once-through design is ideal for small-scale feasibility tests. Specifically cGMP designed to fit in most lab and fume hoods.

PolarDry Model 001

Designed for a laboratory environment, this portable, PLC-controlled, once-through design is the choice for feasibility checks. cGMP design assures full features in a compact footprint.

PolarDry Model 004

A semi-portable, PLC-controlled, recirculating system well suited to R&D environments. Using the same nozzle as other popular PolarDry models makes it easier to scale up from one machine to the next. Includes portable access stairs and a work platform.

PolarDry Model 032

A modular, PLC-controlled intermediate system for pilot environments, model 032 gives you the choice of Batch Architect™ or Batch Architect Pro™ software with 21 CFR Part 11 compliant data logging. Includes access stairs and a work platform.

ELECTROSTATIC DRYER SPECIFICATIONS |

|||||||||

| MODEL 0.1 | MODEL 001 | MODEL 004 | MODEL 032 | MODEL 050 | |||||

| Nom. Evaporation Rate (kg/hr) | 0.1 | 1 | 4 | 30 | 50 | ||||

| Min Drying Temp. (°C) | 20 | 20 | 10 | 10 | 10 | ||||

| Max Drying Temp. (°C) | 200 | 140 | 140 | 140 | 140 | ||||

| Max Drying Gas Flow (m3/hr) | 8.5 | 42 | 170 | 1020 | 1784 | ||||

| Max Atomizing Gas Flow (m3/hr) | 3 | 10 | 17 | 68 | 120 | ||||

| Collection Volume (liters) | 0.25 | 1 | 20 | 14 | 20 | ||||

| Drying Gas Heater | Electric | Electric | Electric | Electric | Indirect Gas | ||||

| Gas Handling | Once Through | Once Through | Recirculating | Recirculating | Recirculating | ||||

| Feed Stock Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Nozzle Clog Monitoring | - | - | - | ✓ | ✓ | ||||

| WIP Nozzles Included | - | - | ✓ | ✓ | ✓ | ||||

| Filter System | Patent Pending Filter Bag | Patented Reverse Pulse Bag | Patented Reverse Pulse Bag | Reverse Pulse Cartridge | Reverse Pulse Cartridge | ||||

| Controls | NEMA 4X | NEMA 4X | NEMA 4X | NEMA 4X | NEMA 4X | ||||

| Controls Software | Batch Architect | Batch Architect | Batch Architect | Batch Architect | Batch Architect | ||||

Superior End-Product Stability

In a recent laboratory study, PolarDry electrostatic drying at 70°C, produced a more homogeneous dry powder of a temperature-sensitive formulation with greater stability and shelf life. This opens the door to a wide range of commercially viable opportunities across pharmaceuticals, nutraceuticals, cosmetics, foods, agriculture, and other industries.

Temperature-Sensitive Protection

PolarDry spray dryers utilize electrostatic technology to drive water to the outside of the droplet, allowing dramatically lower drying temperatures—from 40°C to 140°C. This leads to efficient drying by forcing the liquids outward, and the liquid layer protects the active components from the physical stress of the drying temperatures.

Space and Cost Efficiency

PolarDry systems feature small footprints to reduce maintenance and installation costs. Disposable inner liners make cleanup and changeover easy. Plus, many features and components are shared across the product line, streamlining the effort to scale up from one machine to the next.

Environmental Advantages

PolarDry systems feature nitrogen-inerted systems for exceptional safety. Process gas is recycled, virtually eliminating regulatory issues and safety challenges regarding negligible emissions.

Operator Dust Protection

Negative pressure spray chambers feature monitored inflatable seals. Finish material is collected in a centralized system—no cyclones or dust collectors required—and removed via sealed systems. High-efficiency filters feature a dust sensor on the exhaust and HEPA filters on the inlet and exhaust. Finally, wash-in-place nozzles clean the whole spray chamber before opening.

Quick Cleanup and Changeover

A patented liner system benefits overall operation, cleanup, and changeover. FDA-compliant liners are inserted in the spray chamber, covering the vessel walls and forming a thermal barrier that prevents heat loss to the process room and speeds warm-up. The liner may be washed using tank cleaning nozzles then removed for product changeover.

Consistently Precise Results

All PolarDry nozzles are designed by Spraying Systems, a global leader in spray technology. Each nozzle is precision machined to high tolerances to assure consistent droplet formation, and fully analyzed to assure Spraying Systems' high level of technical, droplet data, and analytical support.

Batch or Continuous Process Configurations

As the FDA and other global regulatory agencies push for continuous processing in pharmaceutical production, PolarDry technology is ready to meet your product demands. PolarDry processes incorporate a unique, patented collection/particle separation plenum that can be easily configured for batch or continuous processing.

Process Flexibility

PolarDry machines are designed for maximum customization and flexibility, including:

- Quick set up, thanks to the integration of a disposable inner chamber liner that can be changed in minutes

- Easy turnaround from one run to the next, through a patent-pending cartridge filter with reverse pulsing to ensure steady drying gas flow

- Compact, portable designs, so equipment can be easily transferred from one suite to another

- Models 001 and 004 are on wheels and fully contained, requiring only electricity, a nitrogen intake, and, for Model 004, an outside chiller to operate

- Models 032 and up, require only electricity, a nitrogen intake, and an outside chiller to operate

Designed-In Safety

- Nitrogen-inerting explosion protection

- Redundant oxygen monitor prevents operation if oxygen level is too high

- Rated lid safety lock and monitored inflatable seals prevent the operator from opening the vessel lid if oxygen level isn't safe (Model 004+)

- Heater over-temperature protection

- Emergency stop buttons and monitoring with safety reset; voltage generator resets if amperage exceeds 8 mA, protecting the operator

- Area oxygen monitoring