Efficient Mixing and Granulation

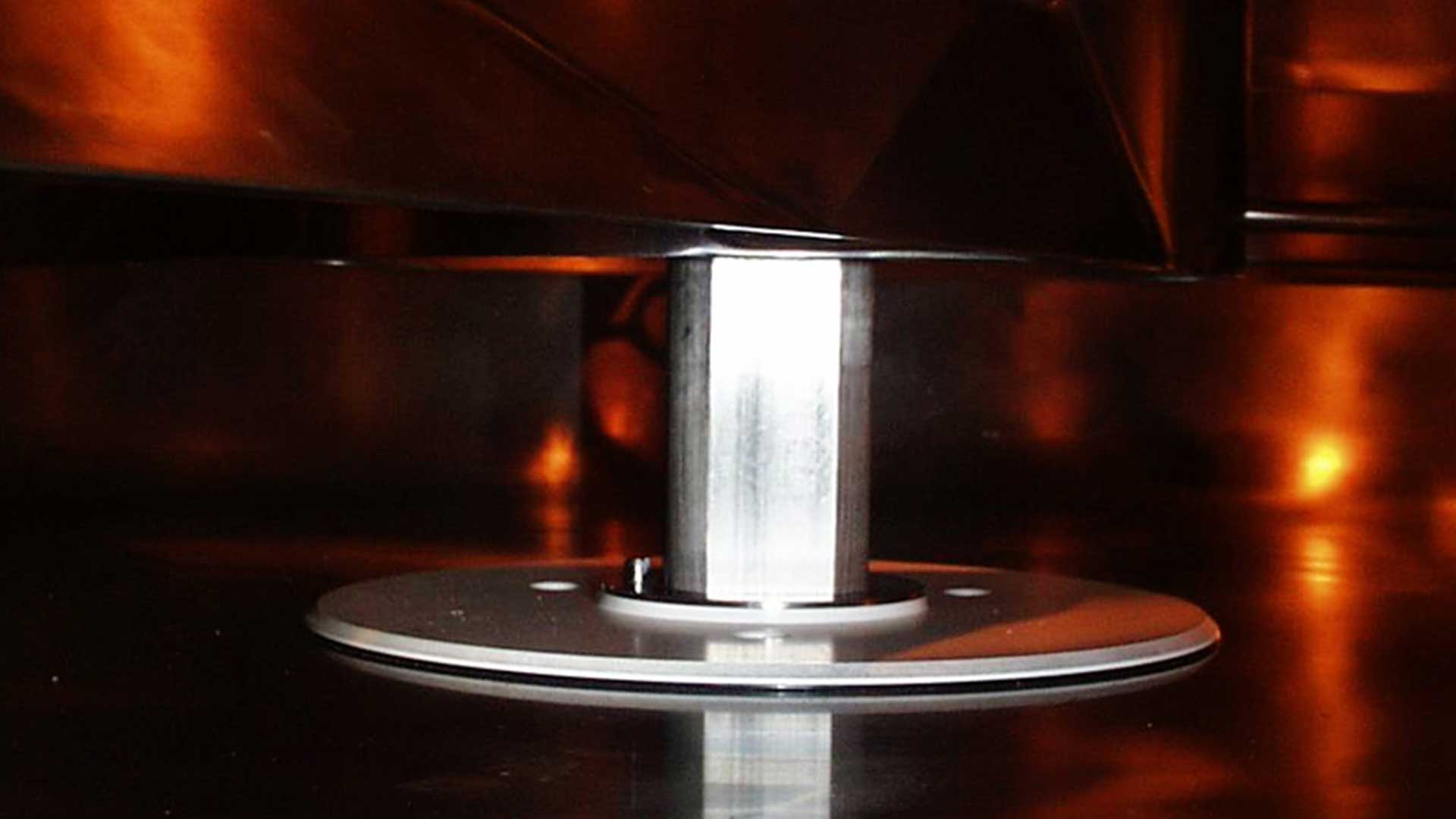

For homogeneous mixing and efficient granulation, PHARMX® high-shear granulators provide fully customizable, bottom-driven mixing with superior results that can boost the value and performance of your end products.

Equipped with an in-bowl, bottom-driven mixing impeller and side-mounted chopper, the PHARMX series assures uniform mixing across a range of R&D, pilot, and production-size models. What's more, you can operate with the bowl at nearly full capacity, maximizing your equipment investment.

PHARMX PX1

Laboratory-scale units provide effective high-shear granulation for small batches.

PHARMX PX25–PX100

Mid-sized systems offer a wide range of options for processing larger batches intended for clinical trial or small-scale production.

PHARMX PX150–PX1250

Large-scale systems are ideal for granulating very large batches, accommodating up to 1,250 liters of material.

MIXER SPECIFICATIONS |

|||||||||

| PX1 | PX25 | PX50 | PX100 | PX150 | PX250 | PX400 | PX600 | PX1250 | |

| Total Bowl Vol. (L) | 1, 2, 4, 6, 8, 13 | 31 | 58 | 119 | 162 | 274 | 432 | 633 | 1286 |

| Charge- Max. Liters @ Light Bulk, 0.3 - 0.5 | 0.9 - 7.5 | 28 | 58 | 107 | 150 | 246 | 389 | 569 | 1157 |

| Charge- Min. Liters | 0.3 - 2.5 | 8 | 15 | 30 | 42 | 69 | 109 | 159 | 324 |

| Impeller Max. Speed (RPM) | 950 | 354 | 289 | 227 | 205 | 172 | 148 | 130 | 103 |

| Impeller Power (HP) | 0.5 | 3 | 5 | 10 | 15 | 40 | 50 | 75 | 150 |

| Chopper Speed Range (RPM) | 1500 - 9750 | 500 - 4000 | 500 - 4000 | 500 - 4000 | 500 - 4000 | 500 - 4000 | 500 - 3000 | 500 - 3000 | 500 - 3000 |

| Chopper Power (HP) | 0.25 | 1 | 2 | 5 | 7.5 | 10 | 15 | 20 | 40 |

Optimize Every Batch

Uniform, Maximized Mixing

The dome-shaped lid permits product to perform a complete rollover as it moves up the side of the vessel wall. This results in efficient mixing, even when running at larger operating capacities.

Constant Tip Speed

Impeller and chopper tip speed is one of the most important factors in high-shear granulation scale-up. All PHARMX bowls are designed to maintain a constant maximum tip speed, and each tool offers infinitely adjustable speeds, to ease the shift from lab to pilot to production.

Safe Processing of Hazardous Compounds

Interchangeable bowls support the processing of potent compounds requiring total containment. Charging and discharging from the mixer bowl is completely contained, and bowls can be removed from the console and placed in a glove box or flexible containment structure without dusting.

Auto-Cleaning and Seal Purging Systems

Fluid Air systems utilize a recipe that flushes and drains the seal purge system and cleans the bowl, tools, and discharge. Combined with a liftable tool system, this greatly simplifies cleaning. What's more, The multistage seal purging system permits operating at low and high seal flows. This helps prevent dusting when loading and allows setting of the flow to match your products' characteristics.

.png?h=75&mh=150&w=358&hash=36844D2DB3DBD3A749E8E7C5AF4A49AA)