Top-Spray or Fluid Bed Agglomeration

The fluid bed granulation process, also known as top-spray agglomeration, can be an ideal approach for pharmaceuticals, as well as food and beverage powders, fine chemicals and cosmetics—without compromising on the initial powders' properties.

This method involves using an air stream to suspend particulates in a fluidized bed. Liquid is sprayed from the top down, wetting particles so they stick together when they collide. As they adhere, they can form granules with a variety of specific properties, such as size distribution and density, to meet your specifications.

Electrostatic Agglomeration

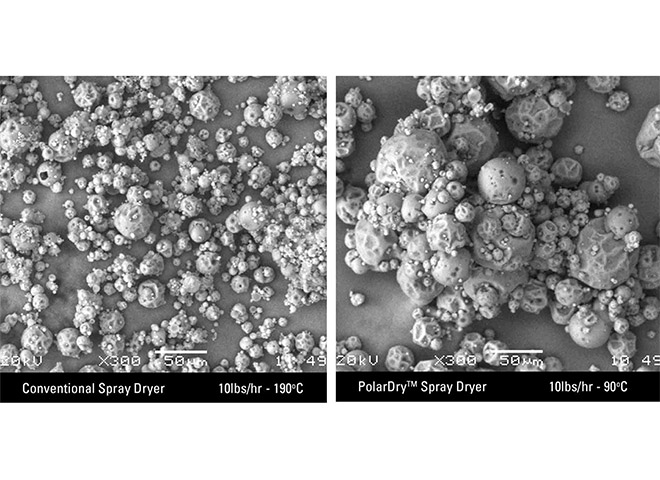

Agglomeration while spray drying is emerging as a cost- and time-effective alternative to traditional granulation methods, precluding the need for multiple processes. This patented technology, Pulse Width Modulation, applies an intermittent electrostatic charge to the feed.

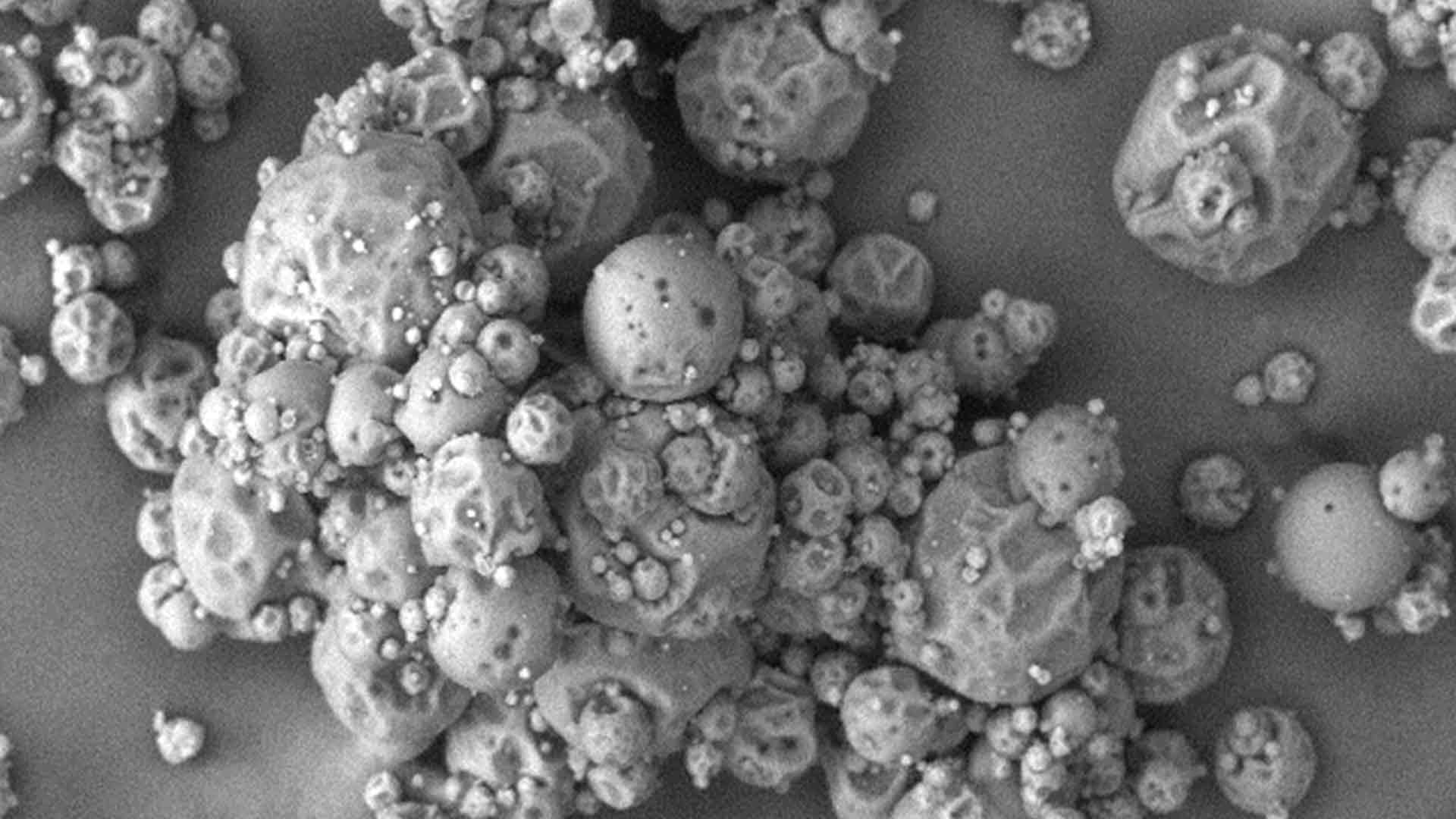

When voltage is precisely applied to the spray droplet as it is being atomized, some particles readily form an outer shell while others develop a shell gradually, resulting in a wet or tacky particle. As these two types of particles collide, they bond to form an agglomerated particle. This results in a free-flowing finished product with larger particles and fewer fines.

.png?h=75&mh=150&w=358&hash=36844D2DB3DBD3A749E8E7C5AF4A49AA)